Proposed Factory for Lahaina Relief

Warning: Array to string conversion in /var/www/wp-includes/formatting.php on line 1096

HomeLahaina Relief

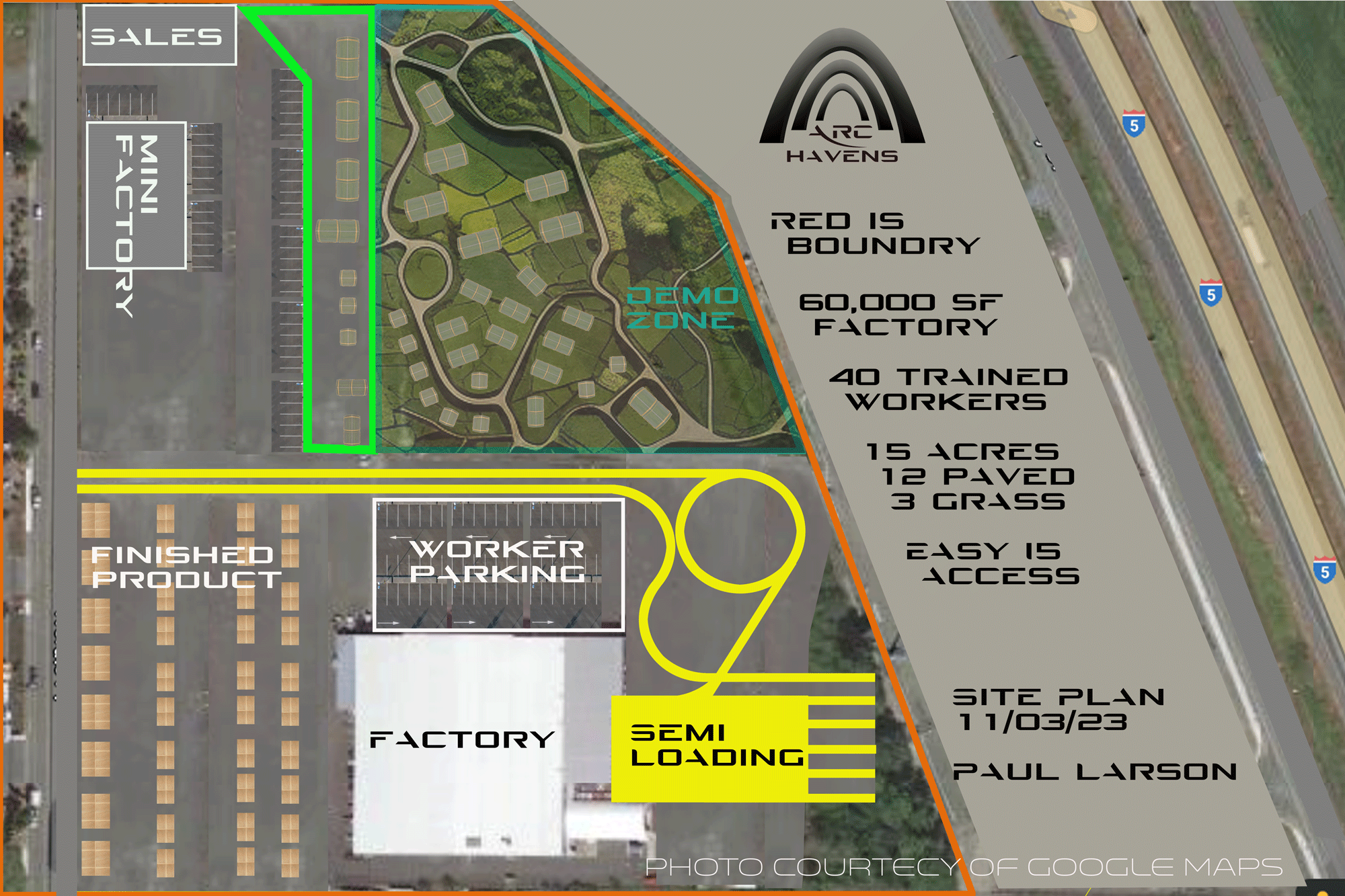

Available factory and site with proposed overlay

Lahaina Relief Plan

Onsite Stick built homes make no sense

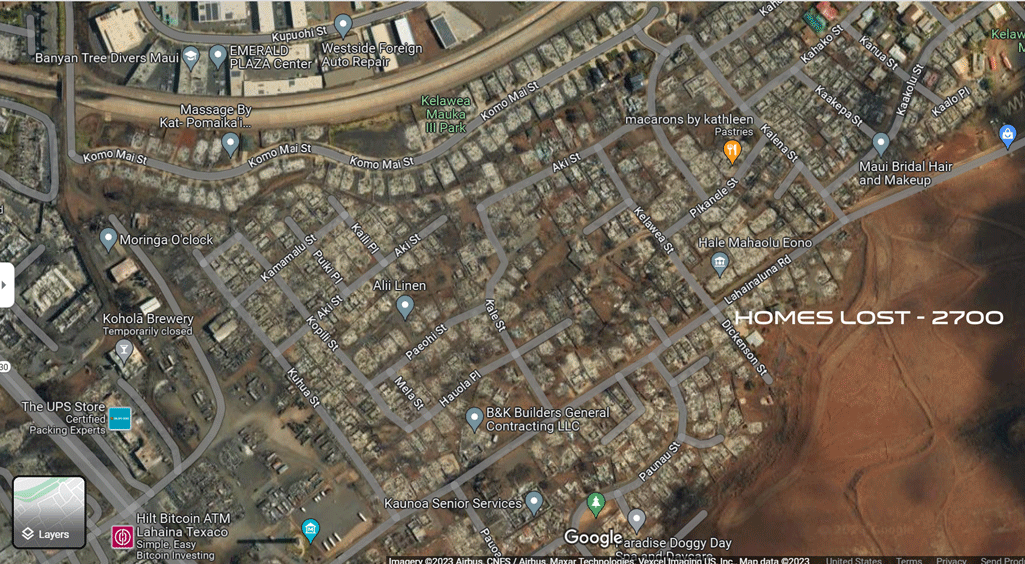

After the devastating fires in Lahaina, HI in 2023, there is a need to supply homes to the affected residents. However, the cost of stick-built homes constructed in Hawaii is prohibitively expensive due to high building costs and a lack of available labor. To address this challenge, we propose building factory-built prefab homes in Bellingham, WA and shipping them to Lahaina. This plan outlines the steps involved in implementing this solution, taking into consideration the given conditions and available resources.

Solution Overview

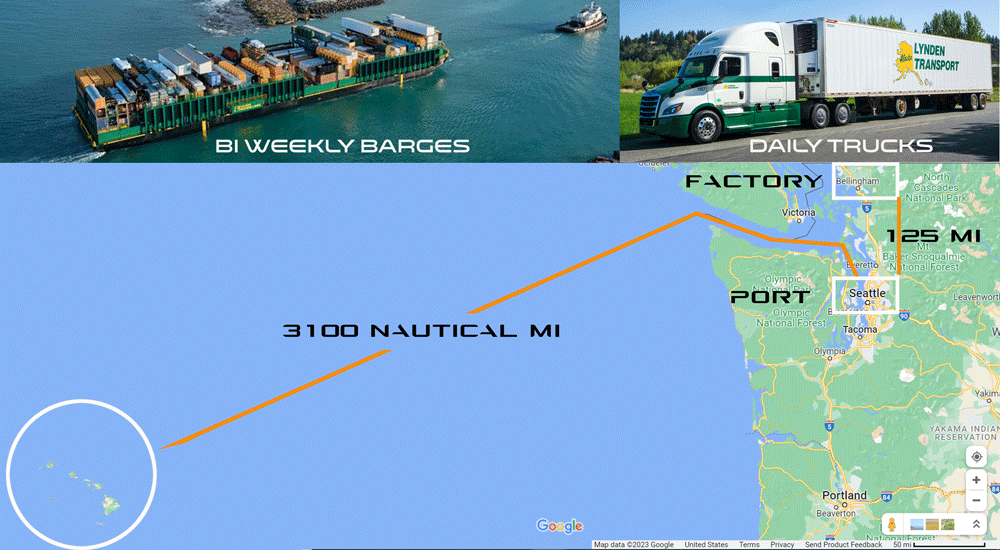

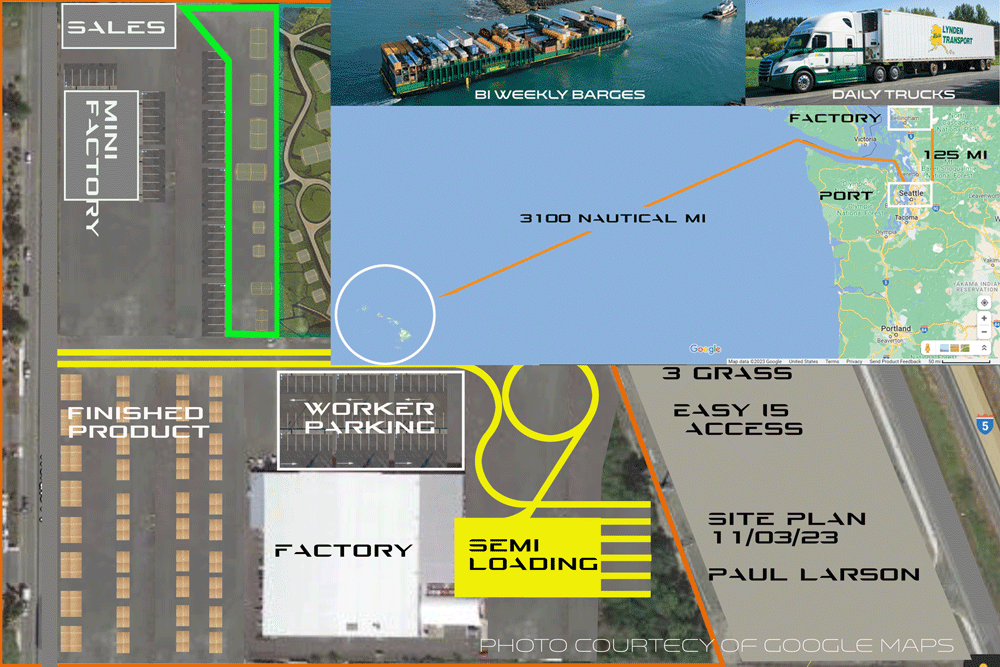

The proposed solution involves constructing factory-built prefab homes in Bellingham, WA, utilizing the abundant supply of Canadian lumber and the availability of a 60,000 square foot factory in Bellingham, WA for lease. These prefab homes will be designed to be flat packed, allowing for efficient transportation. Lynden Shipping will be utilized to transport the flat packed crates from Bellingham to Honolulu, with regular truck shipments to Seattle and bi-monthly barge shipments to Honolulu.

40′ containers can be delivered directly to a central location in or near Lahaina.

Steps for Implementing the Solution

Step 1: Design and Construction of Factory-Built Prefab Homes

1.1. Define the structure of prefab homes: Create a class called PrefabHome that represents a prefab home, with properties such as dimensions, weight, and materials used. DONE

1.2. Develop flat packing algorithm: Create an algorithm to flat pack the prefab homes efficiently into crates for shipping. Implement a function called flat_pack_homes that takes a list of PrefabHome objects as input and returns a list of crates. IN PROCESS

1.3. Calculate shipping cost: Develop a function called calculate_shipping_cost that takes a crate as input and returns the shipping cost based on its weight and dimensions. In Process

1.4. Determine optimal shipping route: Create a function called determine_optimal_route that takes a list of crates as input and returns the optimal shipping route. Done

1.5. Generate shipping schedule: Develop a function called generate_shipping_schedule that takes the optimal route as input and returns a schedule of when each crate should be shipped. Lymden shipping barges leave Seattle evey other Friday.

40' Container

One 40′ container can hold one 20′ X 10′ Double unit with room for assembly tools and supplies for assembly team. Subsequent shipments can hold 1-1/3 20′ X 10′ Double units or one complete 20′ X 10′ Triple unit.

3D model shows one 20′ X 10′ Double unit minus floor.

Step 2: Utilizing Available Resources

2.1. Abundant Canadian lumber in Bellingham: Source the required lumber from Bellingham to ensure a steady supply for the construction of prefab homes.

2.2. Lease the 60,000 square foot factory in Bellingham: Secure the lease of the available factory space in Ferndale to establish the manufacturing facility for prefab homes.

Step 3: Flat Packing and Shipping Logistics

3.1. Flat packing of prefab homes: Utilize the developed flat packing algorithm to efficiently pack the prefab homes into crates for transportation.

3.2. Lynden Shipping logistics: Collaborate with Lynden Shipping to transport the flat packed crates from Bellingham to Seattle using their regular truck shipments. From Seattle, utilize Lynden Shipping’s bi-monthly barge shipments to transport the crates to Honolulu.

Step 4: Cost Considerations

4.1. Cost comparison: Highlight the cost advantages of factory-built prefab homes compared to stick-built homes in Hawaii, considering the high building costs and lack of available labor on the island.

4.2. Cost-effective shipping: Emphasize the cost-effectiveness of flat packing the prefab homes, as purely prefab homes that cannot be flat packed would be too expensive to ship, if possible at all.

Conclusion

By implementing this plan, we can address the need for housing in Lahaina, HI after the 2023 fires by supplying factory-built prefab homes from Bellingham, WA. Utilizing the available resources, such as Canadian lumber and the leased factory space in Ferndale, along with efficient flat packing and shipping logistics provided by Lynden Shipping, we can overcome the challenges associated with stick-built homes in Hawaii. This solution offers a cost-effective and timely approach to provide housing to the affected residents of Lahaina.